At Elite Servo Group, we specialize in providing comprehensive servo motor repair services tailored to meet the needs of various industries. Servo motors are crucial components in a wide array of applications, from industrial automation to robotics, and ensuring their optimal performance is vital for the efficiency and productivity of your operations.

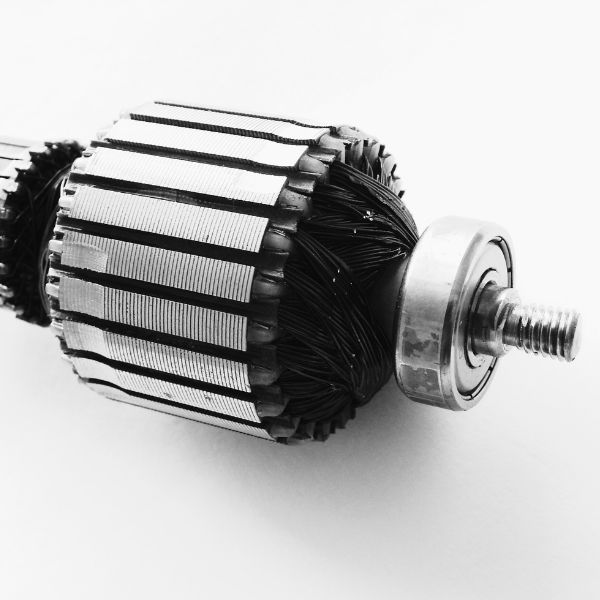

Once the issue is identified, our skilled technicians can do it all: electric motor rewinding, encapsulation, rotor balancing, and waterproofing. A comprehensive test report is provided with every repair.

Protect your motor windings from harsh environmental conditions with a complete epoxy waterproofing procedure.

Balancing a rotor is a critical step in ensuring the reliability, efficiency, and safety. It helps prevent costly downtime, reduces maintenance expenses, and improves the overall performance and longevity of the motor.

MIG, TIG and Resistance welding is part of what we do. We can provide assistance in these areas as well.

We have experience with most brand names drives and motors. We provide complimentary support to help you isolate the issue in your coordinate system. In some cases your motor is just fine and can be the result of mechanical failure. Regardless of the outcome, our primary goal is to get you up and running ASAP!

Yes! Elite Servo Group is a full service facility, offering rewinding, machining and feedback repair.

A few factors to consider: availability, price and lead time. Understanding the customers time constraints determine repair or replace. Expedited repair service offered, fees apply. Request a quote to see if we can help.

Easy, just fill out an RMA form. We'll contact you to guide through the process.

A typical electric motor repair takes 2-7 days. Emergency repairs available, too. Supply constraints may be a factor.

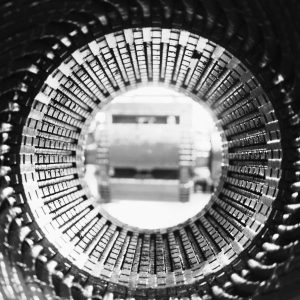

Elite Servo Group uses testing stations specifically created to simulate and check all aspects of your repaired unit. Test reports provided with winding surge test and feedback / efficiency test.

As for today, our testing capabilities allow us to service electric motors up to 200 hp.

Fix the specific machine into manufactured specified safe mode or e-stop. Call our team at (765) 777-3786 to dial in your particular problem. We are more than a repair facility; we are your partner! Send a request here.

Yes! Oil mist applications, cartridge spindles, precision spindles, tool holders and many more.

In most cases, yes, we can provide a quote (here's the form) for a replacement or a repair. Our team has specialized in FANUC repairs for over twenty years and can facilitate a quick turnaround.